What is Ecological Landscaping?

Ecological landscaping seeks to implement a vision of human-designed outdoor spaces that integrate into natural processes.

Ecological landscaping seeks to implement a vision of human-designed outdoor spaces that integrate into natural processes.

If you know how to compost leaves, you can harvest a free source of nutrients and soil benefits for any yard or garden.

Priorities: Broad, Consistent Surface for Outdoor Seating, Garage Access

Challenges: Contour Seamless Edges Around Central Tree

Solutions: Plan Ahead – Cut Stone on Site

The comprehensive services for this residential overhaul were guided by three main objectives.

To meet the needs, Maas Verde planned a masonry patio with 2’x4’ Lueders limestone slabs. Our crew would cut the blocks on site to create aesthetic edges and perfect seams.

Grading with attention to detail would be pivotal to facilitating the even surfaces the clients needed. Rattly stroller passages to the alley-facing garage were not an option.

Finally, Maas Verde would pull up generic plastic bed borders and replace them with long-lasting steel edging. After cutting and welding on site, Maas Verde would fill and plant the beds accordingly.

A custom steel planter box with a trellis put the final touch on the design.

Cutting and welding precisely were the key requirements. Setting “fences” for cuts and laying materials with care made progress methodically. So to keep the timeline efficient, project managers made sure to stay at least one step ahead of the crew.

This way, progress stayed focused, and cut men stayed busy.

Native plantings suited to their sun/shade conditions completed this brisk install.

Ecological landscape maintenance is completely different from mow and blow, and far less costly to clients. Learn more here.

There’s $5,000 on the table from Austin Water for all customers. Here’s Maas Verde’s guide to claiming a rebate.

Priorities: Walkway Safety Hazard – Reduce Pressure on Heritage Oak

Challenges: Tight Scheduling – Balance Elements of Hardscape and Softscape

Solutions: Task Orientation – Detailed Grading

Live in Austin long enough, and you’re bound to lounge on the shady patio at Better Half Coffee & Cocktails.

The spread itself is broad and welcoming, and the live oak that shades it has been there far longer than any of us have been alive. As the holidays approached in 2022, both the hardscaping and the heritage tree needed some care.

Better Half turned to Maas Verde to fix a sloping stone walkway that had become a safety hazard. The path was too narrow to allow two-way foot traffic, and the granite gravel it was bedded in had started to exfoliate onto the stones.

Slip-and-fall incidents became too common as customers and staff jockeyed around each other on the tricky slope.

However, the fix wouldn’t be as simple as mortaring in a walkway. Specifications from a City of Austin arborist dictated no impervious surfaces could cover the tree’s root mass. Recently decompacted via air spading, the area must now remain open to water absorption, and resilient to foot traffic.

Finally, Maas Verde faced a scheduling challenge. Cooler temperatures and holiday crowds meant busy days were getting busier, and the restaurant would soon place its permanent winter tents on the patio.

“In every aspect, the project not only addressed aesthetic problems, but functional ones,” Maas Verde founder and president Ted Maas explained. “This eroding slope ended in an asphalt cake, and the granite gravel created a slip hazard. We needed to put in a patio that would secure all that, handle heavy traffic, and float on top of the tree roots with no excavation.”

Maas Verde met the parameters by resetting the existing stone on a decomposed granite bed, then adding a second row.

A mulch layer around the tree helps cushion any shallowly-buried roots.

Grading the decomposed granite below the stone surfaces, and then coating it with a non-toxic stabilizer, limits its tendency to dislodge.

At the bottom, Maas Verde placed a cut limestone step to provide retention and maintain the overall grade.

Maas Verde worked efficiently to get out of the way of the tent install crew. Project manager John Harris visited the site for a final walkthrough days later, after the tent crew had started work.

“It wouldn’t have been impossible to do this job with those guys there at the same time,” he said, pausing. “But it would have been close to it. They were working right on top of our job site — which was also an early test of concept.”

Better Half said the walkway has made the courtyard safer, and reported no further slip and fall incidents as of this writing.

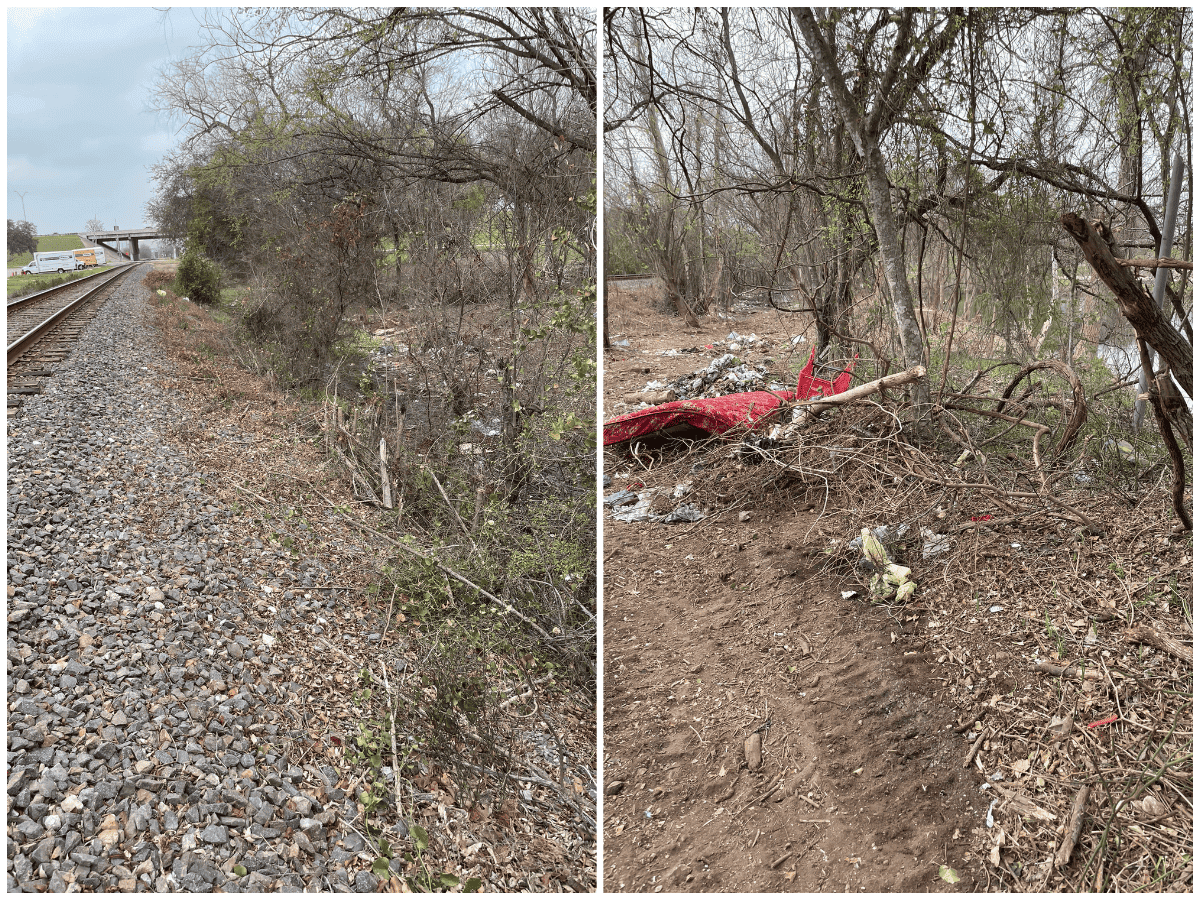

Priorities: Remove Dense Brush – Treat for Prevention

Challenges: Tight Corridors – Trip Hazards – Pollution

Solutions: Safety Focus – Teamwork Between Operators and Ground Crew

Supervisory staff at a Central Texas farm supply company had big plans for a 4-acre swath of undeveloped land at its corporate headquarters. But the parcel would need a lot of work first.

The land was choked with invasives like ligustrum (L. lucidum), Chinaberry (Melia azedarach), and Chinese tallow (Triadica sebifera). Vines climbed into taller trees in thick curtains. And the site’s close proximity to a major highway, a set of railroad tracks, and a retention lake had led to persistent unsanctioned camping and trash problems.

Plans existed for the site to become a “retreat,” where the company’s corporate staff could take relaxing work breaks in the form of meditation, yoga, and outdoor lunches.

The scope of work included removing and herbiciding invasives, then mowing the remaining brush and limbing trees up to eight feet high to clear the understory.

Maas Verde first assessed objective hazards. Trash, both visible and hidden among the thick brush, was an injury and/or disease risk. Narrow corridors meant operators couldn’t drive machines through some areas — and that in others, they would have to work closely alongside the ground crew. Chainsaw operators needed to remain cognizant of trip hazards in between cuts. And a barbed wire fence cut through the middle of the work area.

Key equipment included two skid steers, one mounted with a grapple bucket and one with a forestry mower. The ground crew used chainsaws and backpack sprayers.

The crew cleared the land to spec safely and methodically. Once the ground crew swept an area, the machine with the grapple bucket removed piles of downed brush. The forestry mower then removed remaining vegetation and mulched the area.

Andy Maas, who managed the project for Maas Verde, explained the team’s approach.

“Cutting the unwanted brush and treating those cuts was the main priority. We also thinned a lot of the vines,” Maas said. “This site was so overgrown, and some of the work areas were very challenging. To finish the job without any safety issues was our goal, and we accomplished that.”

Maas Verde hauled off remaining material that couldn’t be mulched, concluding all scopes of work.

Priorities: Safe Landscaping For All Ages – Engaging Natural Play Structures

Challenges: Poor Drainage – Tight Safety Constraints

Solutions: Deep Excavation – Expert Auditing – Creative Design Choices

St. George’s Episcopal School needed a long-planned playground rebuild. The existing grounds covered over two acres, but did little to add learning or play opportunities for the school’s young students. Outdated play fixtures and degraded surfaces were the general rule.

The school’s lead administrator, Jerri Thompson, has a career-long early childhood development background with a specialty focus on natural play. A natural playground focuses on play structures built with elements and textures from the earth, instead of plastic or steel.

In concept, natural playground designers create safety-compliant equipment and play areas with components like logs and stumps, boulders, plants, and mixed, natural surface materials. That’s exactly what Thompson and St. George’s wanted.

(Read the full story here. Or, stay on this page for a scope-focused report.)

Design/Build

Design/BuildMaas Verde tasked its in-house playground designer, Marc Opperman, on the project. Opperman brought over a decade of natural playground design experience to the job. He had also developed some familiarity with the site itself by creating previous partial designs for the space.

Maas Verde began deep excavation work in early April, and worked on site daily for the next eight weeks. The final install includes log-and-lumber pergolas, log climbing structures, lawns and drainage swales, multiple new trees, shrubs, and planting areas, and even fountains — all of which meet playground safety regulations.

The space breaks down into four main areas: three playgrounds designed for students in different age brackets, and an entryway area with a fountain and some sculpture installations.

Maas Verde measured out prescribed fall zones for play structures including climbing equipment and swingsets. Opperman chose natural materials instead of synthetic options in all applications. Borders between walkways and play pits are Juniper logs instead of segmented plastic edging. And vertical structures like the logs for climbing (fitted with real, commercial-grade resin climbing holds) are edge-chamfered for safety. Ground surfaces like mulches and pea gravel can break a fall but still create a consequence.

Two cambered “race tracks” function the same way. Toddlers and infants race toy vehicles down the slopes, honing their spatial reasoning. Runout zones are grass and mulch berms.

Artificial surfaces and exhausted fixtures came out, improving safety and updating appearance. Maas Verde removed astroturf and rubber bumpers surrounding a playscape, then replaced it with a mulch bed and the site’s signature log borders.

An existing shade sail had failed, so Maas Verde tore it out and installed a pergola. And bright white play sand replaced gritty aggregates in play pits.

Hidden obstacles included hundreds of square feet of unexpected concrete and asphalt buried deep below the existing turf. Deeper excavation was the only option.

A drainage flaw surfaced during one heavy rain. Water pooled on the playground surface and backflowed toward the main school complex. Maas Verde redrew plans to build in a grassy swale that would redirect the water back toward absorbent areas of the playground.

A previously installed, 25-foot-long creek runs on a solar-powered pump. The feature is a design centerpiece, but requires maintenance: heavy weeding and marginal drainage are concerns. Per Thompson’s priorities, Maas Verde will adopt the creek along with its ongoing maintenance plan.

Carefully-chosen plantings complete the design. Plants should be visually stimulating but tough enough to survive inquisitive toddlers.

“For me, this is the vision of my entire career,” Thompson said. “Schools are clamoring to install things like these, and you can see why.”

Opperman summed up the transformation: “Before we started, it had the feel of something made in the ‘70s — it was kind of neglected. Now, it’s not only updated but it’s got natural materials and passes safety compliance.”

Priorities: Troubleshoot Prolonged Irrigation System Failure

Challenges: Multiple Failed Prior Attempts – No Plan Documents – One Urgent Scope

Solutions: Trace Underground Faults – Expedite with Key Equipment

Maas Verde received an initial, urgent call from a nonprofit working to donate a handful of trees to West Texas’ Balmorhea State Park.

The organization needed a fast irrigation repair for an upcoming event held in conjunction with the donation. The planted trees were wilting in the desert landscape, partly because the park’s irrigation system had not functioned since before the current park supervisor’s two-year tenure.

Maas Verde had four days to find a solution for the expedited work order. After that, the team would lean into a repair of the park’s entire system — which tunnels under the park’s turf, asphalt, sidewalks, and even canals for thousands of feet.

(Read the full story here. Or stay on this page for a scope-focused report.)

Our technicians loaded up material, troubleshooting tools, and digging equipment at our Austin headquarters and moved out via I-10.

When they arrived at the park, superintendent Torrey Bonham provided an orientation that was as complete as possible.

Despite Bonham’s substantial efforts, he could not possibly collect all the relevant information, which had degraded throughout previous administrations. Multiple prior contractors had worked on various pieces of the 12-zone system, but none had resolved its functional issues.

Maas Verde first determined the system needed a new controller, and that an attempted line to irrigate the new trees had failed. The team determined that rather than remediating the existing equipment, installing a new line was the only viable option.

But the system’s large scale forced us to source components from the nearest irrigation supplier, 90 minutes away in Odessa. The 130 PSI pump pushed water through pipe up to 4” — on scale, the network rivals golf courses.

The team logged overtime daily to complete the first install on schedule. The only way to expedite the process was to trench and dig with a mini skid steer and excavator.

Once Maas Verde successfully added the zone, the full system remediation began.

The team could only locate underground faults one at a time. Technicians could only locate the next electrical failure or pipe leak by tracing it downstream from the last one.

Scrambled componentry representing the layers of prior installs and attempts made the work more puzzling. An emergency sewer repair was the unexpected cause of one severed wire; the tree-planting subcontractor had destroyed several feet of pipe with an excavator but done nothing to report it; miswired solenoids had shorted out and no longer operated.

Balmorhea’s irrigation system was big, sprawling, and convoluted.

Resolving breakages demanded using a ground fault locator and other specialty tools, but deep landscape experience was critical to success. Reading subtle surface conditions like linear swales and concrete repairs helped the team decide where and how to excavate safely and effectively.

The team solved each fault as it surfaced. Through this process, we began mapping the system and eventually developed an understanding of its full scope and operation.

Finally, Maas Verde excavated an old valve buried in an obscure location below several inches of natural turf. This hidden component proved to be the last missing link in the system. Our technicians incorporated it into the system, confirmed each zone operated from the controller, and concluded the project.

View this post on Instagram

Maas Verde designs and builds a natural playground with strong input from an experienced child educator.